- Contact Us

- |

- Jobs

- |

- About Us

- |

- |

-

- Personal information

- Organization

- Quotes

- Address book

- Login

- Don't have an account? Sign-up

Knitted wire mesh gasket

- Home

- EMI shielding gaskets solutions

- EMI shielding gaskets

- Knitted wire mesh gasket

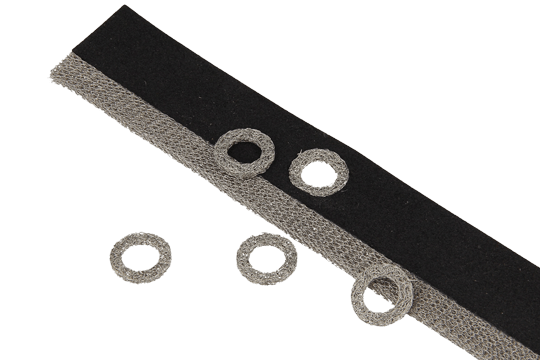

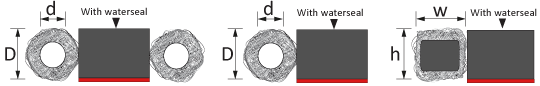

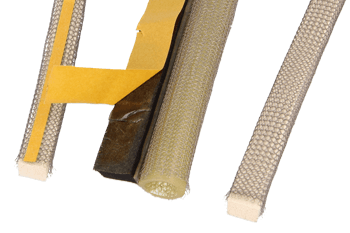

The knitted wire mesh EMI/RFI shielding gaskets consist of a layer of knitted electrically conductive metal wires attached to a low-closure force rubber or elastomer core. For heavy-duty applications like EMP or high temperatures, a full metal version is available. Sometimes a Metal knit EMI/RFI gasket is combined with an environmental seal to provide IP rating, depending on the materials used.

Knitted wire mesh gaskets provide a cost-effective solution to high shielding performance applications in the magnetic and electrical fields, including EMP. The gaskets can be made either completely from knitted metal mesh or from knitted metal mesh over an elastomer core which allows recovery after compression.

For high-frequency shielding, foil-based gaskets like Amucor Shield will perform better, because of their much larger contact surface.

Knitted wire mesh gasket vs. Amucor shield

Benefits

- High attenuation for lower frequencies (low-frequency magnetic shielding)

- Suitable for use under extreme conditions (military applications)

- Wear-resistant

- Not susceptible to corrosion

- Various conductive materials against tension corrosion

- Roll lengths of 1 to 1000 meters (depending on width and height of the gasket)

- Tools required: pair of scissors

Options (on request)

- Custom made in the dimensions specified

- Available with flame-retardant core

- Available with conductive self-adhesive

- Available with chemical-resistant rubbers like EPDM

- Silicone sponge for high temperatures up to 220 °C

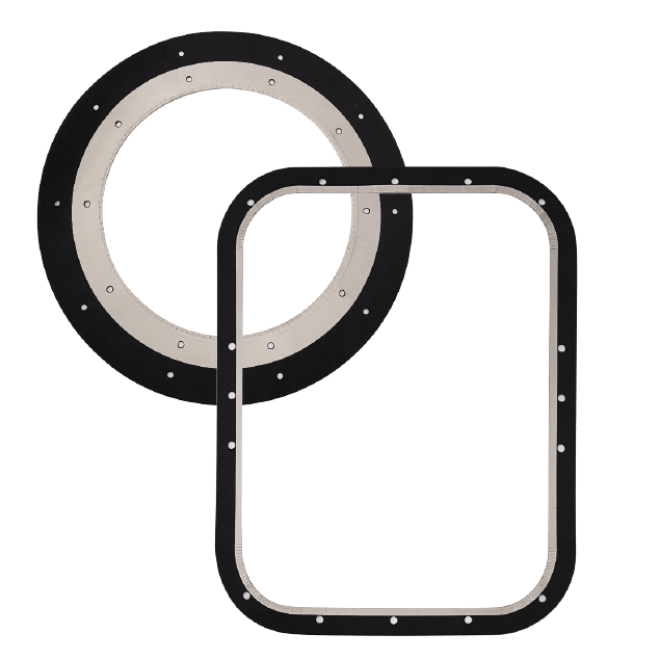

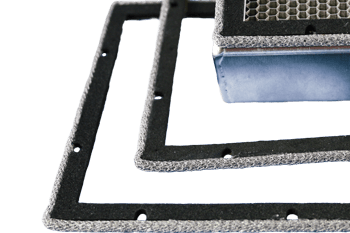

- Cut into accurate lengths as a ready-made frame

Stock dimensions

Below are all the standard sizes we keep in stock and so are available quickly. Almost any size and combination can be produced. If you need a size that is not listed below please contact for the options and delivery time.

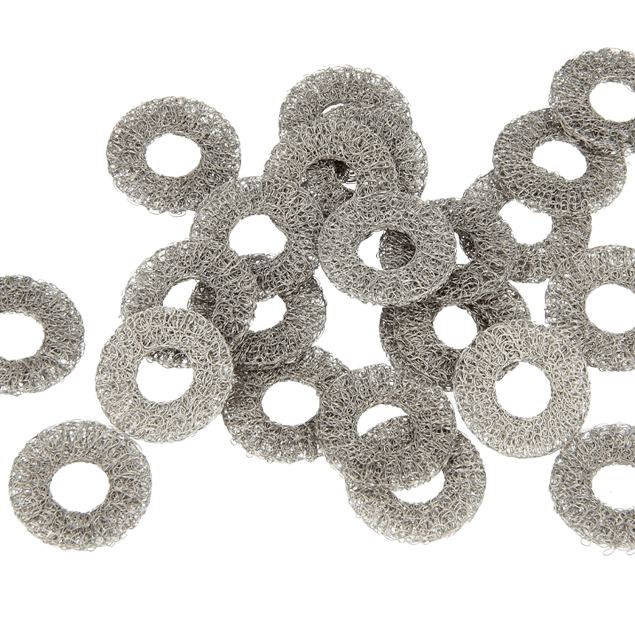

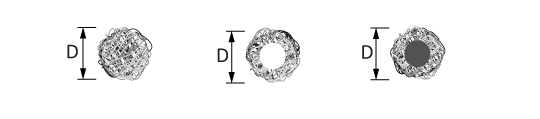

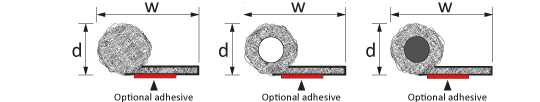

Round (R)

| D (mm) or D x d (mm) | ||

|---|---|---|

| 1.6 | 4.8 x 3.2 | 9.5 x 6.4 |

| 2.4 | 6.4 | 11.1 |

| 3.2 | 6.4 x 3.2 | 11.1 x 8.0 |

| 3.2 x 1.6 | 7.9 | 12.7 |

| 4.0 | 8.0 x 4.8 | 12.7 x 9.5 |

| 4.8 | 9.5 | 14.9 x 11.1 |

Double round (DR)

| d x w (mm) | ||

|---|---|---|

| 1.6 x 9.5 | 3.2 x 12.7 | 6.4 x 15.9 |

| 1.6 x 12.7 | 3.2 x 15.9 | 6.4 x 19.1 |

| 1.6 x 15.9 | 4.8 x 15.9 | 6.4 x 25.4 |

| 2.4 x 12.7 | 4.8 x 19.1 | 9.5 x 25.4 |

| 3.2 x 9.5 | 4.8 x 25.4 | 12.7 x 25.4 |

| 3.2 x 39.0 | ||

Round with tail (T)

| d x w (mm) | |||

|---|---|---|---|

| 1.6 x 9.5 | 3.2 x 15.9 | 6.4 x 12.7 | 9.5 x 19.1 |

| 1.6 x 12.7 | 3.2 x 19.1 | 6.4 x 15.9 | 9.5 x 25.4 |

| 1.6 x 15.9 | 4.0 x 12.7 | 6.4 x 19.1 | 11.1 x 19.1 |

| 1.6 x 19.1 | 4.0 x 19.1 | 6.4 x 25.4 | 11.1 x 25.4 |

| 2.4 x 12.7 | 4.8 x 12.7 | 7.9 x 15.9 | 12.7 x 19.1 |

| 2.4 x 15.9 | 4.8 x 15.9 | 7.9 x 19.1 | 12.7 x 25.4 |

| 2.4 x 19.1 | 4.8 x 19.1 | 7.9 x 25.4 | |

| 3.2 x 12.7 | 4.8 x 25.4 | 9.5 x 15.9 | |

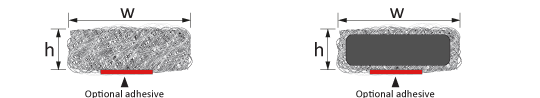

Rectangular (S)

| Rectangular (S) | ||

|---|---|---|

| 3.2 x 1.6 | 9.5 x 3.2 | 19.1 x 12.7 |

| 3.2 x 2.4 | 9.5 x 4.8 | 20 x 6 |

| 3.2 x 3.2 | 9.5 x 6.4 | 20 x 8 |

| 4.0 x 3.2 | 12.7 x 6.4 | 20 x 10 |

| 4.8 x 2.4 | 12.7 x 9.5 | 20 x 12 |

| 4.8 x 3.2 | 12.7 x 12.7 | 20 x 20 |

| 4.8 x 4.8 | 15 x 6 | 25 x 6 |

| 6.4 x 1.6 | 15 x 8 | 25 x 8 |

| 6.4 x 2.4 | 15 x 10 | 25 x 10 |

| 6.4 x 3.2 | 15 x 12 | 25 x 12 |

| 6.4 x 4.8 | 15 x 15 | 25 x 18 |

| 6.4 x 6.4 | 15.9 x 9.5 | 25 x 20 |

Shielding performance

In house knitted wire mesh production video

Technical specifications

| Material | Applications |

|---|---|

| Monel Per QQ-N-281 BS 3075 N A 13 Class A diameter 0.11mm |

The most commonly used material. Insensitive to corrosion and neutral on the galvanic scale. |

| Aluminium AMS 4187 BS 1475 5056A Alloy 5056 diameter 0.16mm |

Used in some cases for aluminium enclosures. |

| T.C.S. Steel core (57%) Copper cladding (40%) Tin plating (3%) diameter 0.11mm |

Excellent magnetic as well as electrical properties, because a Ferro alloy is covered with copper. The outside is tinned to prevent corrosion. |

| Stainless steel AISI 304 diameter 0.13mm |

The strongest material with shielding performance comparable to aluminium. Highly wear-resistant. |

With water seal/IP seal

All knitted mesh EMI/RFI gaskets can be produced with a water seal/IP seal.

The standard material for the fluid seal/water seal is Neoprene which can be adhesive-backed (indicated in red in the drawings) for easy installation. Alternatively, a silicone sponge is also available.

Optimum compression/density

The maximum deflection with a sponge elastomer core is approximately 30%, with hollow extrusion 50%. This is why the hollow type is used more often. Compression levels are important in applications such as liquid filtration and noise attenuation, where flow resistance is critical.

Applications

Used to seal enclosure lids and doors, removable cover plates and interface gaskets for EMI shielded vent panels and EMI/RFI shielded windows.

Temperature resistance

Temperature resistance depends on the core material of the metal knit EMI/RFI gasket; ranges from -60 °C up to 220 °C are possible. These Metal knit EMI/RFI gaskets are insensitive to external influences and can withstand harsh conditions very well.